Estimated reading time: 8 minutes

Would you love to be able to make essential oils from your fruit trees? Essential oils are a wonderful gift from nature and are incredibly useful.

Most people are probably most familiar with using sweet-smelling oils to make their house smell divine or adding a few drops to perfume their bath.

But their value goes way beyond that.

Related Articles

Will subtropical fruit trees work in your garden?

A lot of subtropical fruit comes from indigenous forest cultures, but that doesn’t mean you can’t grow it in your backyard.

Animals, fruit trees, and electric fences

Animals and fruit trees go well together if you can figure out how to enjoy the benefits without the animals doing too much damage.

Warming winter cakes with home-grown fruit

Bake delicious warming winter cakes from the fruit you’ve grown on the fruit trees in your own garden for extra satisfaction.

Did you know that most oils also have medicinal properties? Eucalyptus, tea-tree, and lavender oils in particular are known for their antibacterial, antifungal, and antiviral properties.

The famous Four Thieves Oil (or vinegar) was a concoction of essential oils and herbs created during the Great Plague of London in 1665. It reputedly prevented people from catching the disease (and was apparently effective in allowing thieves to safely rob the dying, hence the name).

At our place, they’ve long been a vital part of our home first-aid kit. They help to fix everything from cuts and colds to bad cases of croup.

Essential oils have always been part of our lifestyle. We love their healing, cleaning, and restorative properties.

But what we particularly love is that many of the common and most useful oils come from fruit trees and other plants that you probably have in your garden.

Orange, lemon, grapefruit, mandarin, myrtle, cypress, and juniper trees all yield wonderful smelling oils.

Flower oils are often of most interest to backyard growers. That’s probably because flowers are much easier and faster to grow, and easier to harvest than some of the woodier oils that come from trees.

Think rose, lavender, boronia, jasmine, chamomile, geranium, and juniper. And then there are the herbs like basil, marjoram, fennel, melissa, thyme, and peppermint.

How to make essential oils at home

Hardly anyone makes their own essential oils at home, and there’s a very good reason for that.

It’s not easy!

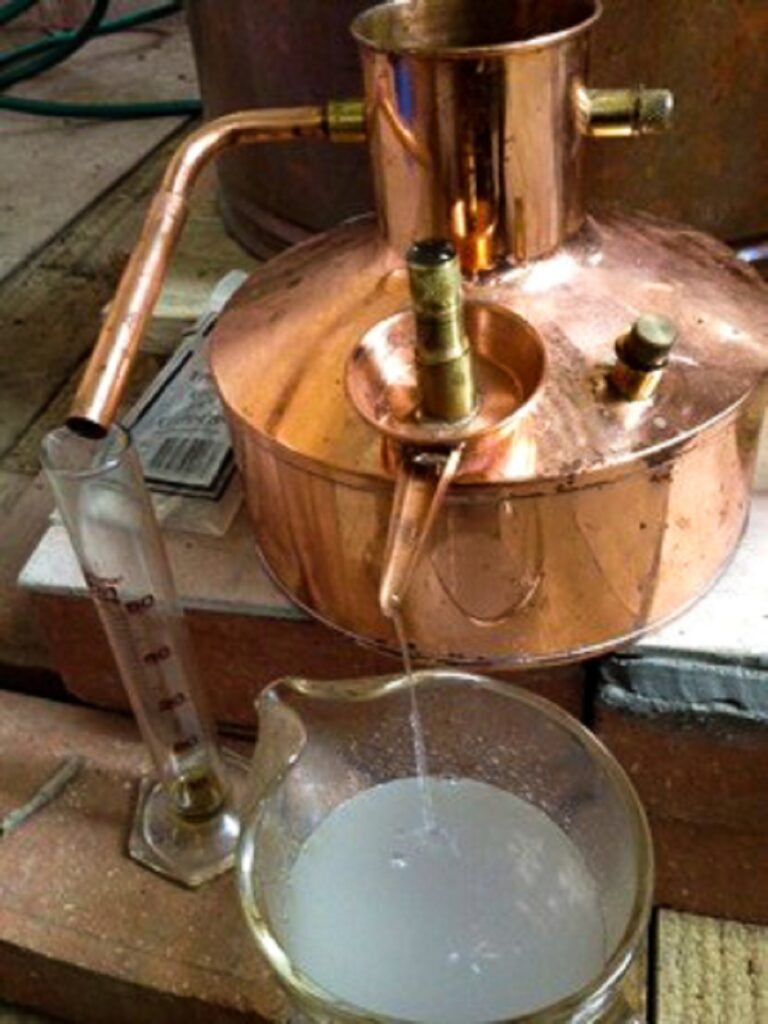

Oils are made by distilling plant material, including bark, leaves, flowers, and fruit.

For a start, you need to have the right plants growing, you need to know which parts of the plant to harvest, and the right technique and timing for getting the plant material in top-notch quality.

Then, you need a whole lot of specialist equipment. Oh and on top of that, you need the skills.

Luckily, we happen to have some experts on hand.

Learning the process

Former Grow Great Fruit member Tuesday from Wild Crafted Oils produces a fantastic range of essential oils on her property in Torrumbarry.

She also runs workshops so you can experience the whole process for yourself.

Tuesday was kind enough to share the entire process of creating stunning Neroli essential oil from orange blossom flowers so we could share it with you.

And yes, we’ve smelled it, and yes, it’s divine!

One of the things to consider when harvesting flowers from your fruit trees is that you’re reducing the amount of fruit the tree can produce. Flowers can only be used once, so if they’re harvested for oil, they obviously won’t be left on the tree to turn into fruit.

In Tuesday’s story, you’ll note that only half the flowers were harvested from each tree. She doesn’t go into detail about the principles of distillation because it’s easy to find that out on the internet but instead shares her personal experience from start to end.

We’ll let her tell the story of how the whole process is done in her own words.

Harvesting the blossoms

“Our first morning’s harvest of orange blossom from the orchard was on 19th Oct 2016. Each morning for 14 days we would take the ute up to the orchard and lay the harvest cloths under each tree.

In all, we picked over 350 kg of blossom over the 14 days. We estimate this to be around 50% of blossom available. If we had more pickers and a very efficient still we could process an estimated 600 kg of blossom from this orchard. But that is in the future.

Bees were well behaved and we were mindful not to get in their way. We used yellow irrigation hoses to secure the harvest cloths down on windy days.

From the orchard, the blossom is transported back to the oil room to be sorted ready for distillation the next day. We have let the blossoms sit for 24 hrs as advised by distiller Guenther. Average 25 kg per day.

Pickers’ notes

- Socks with the toes cut out and used as forearm protection proved mighty good. The area between the wrist and the hand often gets scratched and this helped prevent damage to the arms.

- Long-sleeved shirts, sturdy boots, and good thick gloves add further protection from being scratched and also from being bitten by mosquitoes and bugs.

- Face nets were used to keep bits of nature from falling onto the eyes and face.

- Digging sticks were the perfect length and shape to reach and tap the taller limbs so that ripe blossoms fell on the harvest cloths. We noted the need for opening up the trees for ease of access to the blossoms and will begin to prune trees to suit.

[NOTE: The foolproof 7-step pruning method explains how to prune trees to an open shape for easier harvesting.]

- We also noted the need for being able to identify when a tree had been harvested. Will develop a form that shows each numbered tree so that we can comment as we harvest.

- Harvesting after 11.30 am is not sensible here as the heat is building and the blossom seem to wilt a tad in the middle of the day. So early starts are the go.

Beginning the distillation process

After the sorting, the blossoms are placed in the still in the water ready for hydrodistillation. This is the first time that we have used the still with no column.

The blossom is weighed after the sorting and just prior to putting it into the still so that we get a more accurate account of blossom weight.

Managing the still

Cleaning the still became an issue.

The separator, the condenser, and the bowl all were cleaned with citric acid and came up a treat. This stopped the oil from being darker than we wanted. I need to ensure that the still is cleaned thoroughly with citric acid between each different plant species being distilled. It is all a learning curve.

Wood is collected each day for the firebox which is the source of heat. We noted the need for smaller pieces of wood that burn quickly so that we can maintain 100º C and create a good head of steam.

Overfilling the still with water, i.e. over 120 liters, led to a very long warm-up time. One day we started at 9.30 am with 160 liters of water and 30 kg of blossom and we did not get hydrosol coming out until 5.30 pm! This was the longest day and a great lesson in finding the balance of water to blossom.

Recommend 120 liters with 25–30 kg of blossom. Less than 20 kg of blossom only requires 100 litres.

How much essential oil can you produce?

In all, we have produced 190 litres of Neroli hydrosol and 160 ml of Neroli essential oil. Our ratio will improve as we get more knowledgeable and intuitive about the distillation of Orange blossom flowers.

Each plant has its own character when distilling. Citrus aurantium (bitter orange) certainly is a heady aroma and is not easily coaxed out of the flower petals.

By day 8 our team was satiated with Neroli qualities. We were too tired to go on so we had a day’s rest to enable us to smell nothing except the Australian bush.

We called it a Nerolized stupor.

So, all done and dusted until next October when the blossoms bloom for a few weeks and we begin the story once more. Great harvest and thanks to all. Now to find a good home for the lot.”

Making essential oils from fruit trees (and other plants) is one of those lesser-known homesteading skills. We’re very keen to bring it back (and try it ourselves!).

Many thanks to Tuesday for sharing her experience. It gives a wonderful insight into the reality of value-adding from your backyard on a commercial scale.

160ml of oil from 350kg blossom doesn’t seem like very much, does it? But the fact that they are very highly concentrated is partly what gives essential oils their amazing healing properties.

In fact, when using these oils for remedies or any other use, they are measured in drops. That, combined with the effort and skills involved in producing them are what put the “value” in value-added.

Related Articles

Will subtropical fruit trees work in your garden?

A lot of subtropical fruit comes from indigenous forest cultures, but that doesn’t mean you can’t grow it in your backyard.

Animals, fruit trees, and electric fences

Animals and fruit trees go well together if you can figure out how to enjoy the benefits without the animals doing too much damage.

Warming winter cakes with home-grown fruit

Bake delicious warming winter cakes from the fruit you’ve grown on the fruit trees in your own garden for extra satisfaction.

Hi Hugh,

Thank you for sharing these. I never thought that there is still another use for orange blossoms. I had gained new idea regarding this blossoms.

*very nice post, i certainly love this website, keep on it

Fabulous!

Where can I get such distillation tools? I have amazing pavlonia blooming crazily at the moment! I’d love to distill the smell from that and my prolific jasmine, frangipani and murraya!

Hi Fiona, we’d recommend getting in touch with Wild Crafted Oils directly, as they run distillation workshops and can no doubt answer all your questions.